-

tel: +86 18861951588

-

email: jade1971@163.com

-

WhatsAPP: tengfeiltd(13851019143)

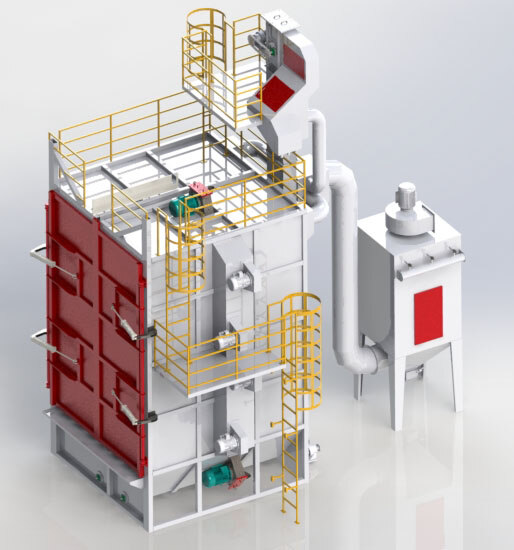

What does the hook shot blasting machine...

Some applications of steel shot in shot blasting process

10 Feb

10 Feb

Hook type shot blasting machine is suitable for surface cleaning or strengthening of various models, medium and small batch casting and forging parts and riveting and welding parts, especially for the surface cleaning or strengthening of slender and thin wall parts that are afraid of collision. We all know that in order to maintain the long-term stable operation of equipment, daily maintenance work is the top priority. Today, we will introduce you to the daily maintenance of the hook shot blasting machine. Point to

1. Before starting the hook shot blasting machine, open the hook shot blasting machine, connect the compressed air to the gas storage tank, and open the control power supply and ash discharge device. If there are other devices in the system, start the downstream device first.

2, in the normal working process, the relevant operators should be very familiar with the performance and operating conditions of the equipment, master the conventional adjustment and maintenance methods, and pay attention to the ash discharge device can not stop working to avoid internal ash accumulation. The equipment stops working;

3. Regular check-ups are very important. Regularly measure the relevant parameters of the product, such as smoke volume, temperature, concentration, etc., and regularly check the working condition of the pressure switch. Change the oil;

4, when the equipment is shut down, after the system is shut down, keep the exhaust fan working for a period of time, and clean the dust. When the equipment is stopped, do not cut off the air source and ensure that the lift valve is open.

The above briefly introduces the matters that should be paid attention to in the daily use and maintenance of the hook shot blasting machine. I hope its helpful.