-

tel: +86 18861951588

-

email: jade1971@163.com

-

WhatsAPP: tengfeiltd(13851019143)

What is the difference between a drum sh...

Some applications of steel shot in shot blasting process

10 Feb

10 Feb

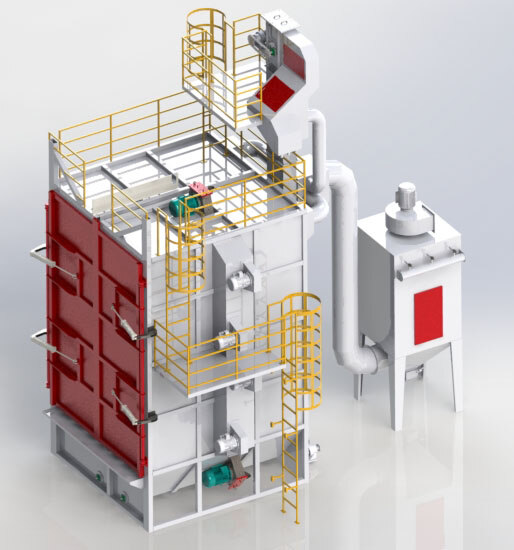

In the field of drum shot blasting machine equipment, there are mainly two aspects: shot blasting and sand blasting. Shot blasting mainly refers to the shot blasting machine, sand blasting mainly refers to the sand blasting equipment. Next, I will introduce the differences and similarities between shot blasting and sand blasting.

Shot blasting is a mechanical surface treatment process that improves the service life of the workpiece.

Sandblasting (sandblasting) is a type of work that uses compressed air as a power to push abrasive onto the surface of the workpiece for treatment. Specifically, it uses compressed air, high-pressure water, steam, etc. to drive the flow of abrasives to clean, strengthen, cut, and erode the surface of the workpiece. The operation process of changing its shape or state, sandblasting is common, but this process is quite slow and not easy to detect.

The purpose of shot blasting and sandblasting is to prepare the workpiece for the next process, not only to ensure the roughness requirements of the next process, but also to make the surface treatment of the workpiece as consistent as possible. Shot peening has a strengthening effect on the workpiece, and its effect is more obvious, relatively speaking, sandblasting is not obvious. Generally speaking, shot blasting is a small steel ball, and sand blasting is quartz sand. Sandblasting is mainly manual operation, while shot blasting is mostly automatic and semi-automatic; Sand blasting uses compressed air as a power to spray sand or shot blasting material onto the surface of the material to achieve removal and a certain roughness. Blasting is a method of blowing the centrifugal force generated by the high-speed rotation of the shot blasting material to the surface of the material to remove and achieve a certain roughness. Whether it is shot blasting or sandblasting, it can clean and purify the workpiece.