-

tel: +86 18861951588

-

email: jade1971@163.com

-

WhatsAPP: tengfeiltd(13851019143)

Some applications of steel shot in shot ...

Some applications of steel shot in shot blasting process

10 Feb

10 Feb

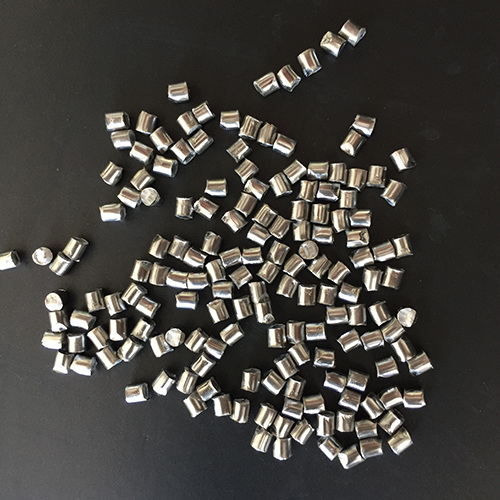

Regarding some applications of steel pellets in the shot blasting process, if we need to obtain uniform roughness, we need to follow the following points when selecting steel pellets: 1. The particle size of the steel ball needs to be uniform, the spherical steel ball requires the diameter to be uniform, the angular sand (that is, the casting steel sand) requires the basic shape of the particles to be the same, and the diameter and length ratio of the steel ball is about 1:1. 2, the initial hardness of the steel ball must be greater than the initial hardness of the workpiece to be cleaned, generally more than the hardness of HRC5 ~ HRC10, in order to obtain a certain roughness; If the initial hardness of the steel pellets is less than or equal to the initial hardness of the parts to be cleaned, a certain roughness will not be achieved. Upon request. 3, the workpiece surface roughness is determined by the diameter of the steel ball. The larger the diameter of the steel shot, the greater the peak-valley drop of the hit workpiece surface, that is, the greater the roughness; On the contrary, roughness is less. 4, ball shaped steel pellets (including cast steel pellets and steel wire cutting pellets, round pellets) and corner shaped steel pellets (including corner sand and steel wire cutting pellets), the roughness of the ball shaped steel pellets on the surface of the hit workpiece is less than that of the corner steel pellets, which is because the corner steel pellets have a certain Angle, through cutting impact, the end with the edge can produce deep valleys on the surface of the workpiece; The spherical steel shot is spherical because the surface is formed on the surface of the workpiece being hit. The valley will be smaller than the angular steel shot. 5, the use of steel wire cutting pills, because there are many ordinary steel wire cutting pills on the market, the length is 3mm, or even 4 ~ 5mm, like a rod, this steel pill will have a certain impact on the shot blasting effect, which is reflected in the following points: 1) When the rod steel shot is shot blasting, if the head touches the workpiece, it can only play the role of cutting the shot, and when the head is round, it can only play the role of circular shooting.

2) If the rod horizontally hits the workpiece, it will only cause the rod to wear in the length direction, will not produce roughness on the key surface, will not play the shot blasting effect, but will cause consumption and affect the shot blasting effect. 3) In the shot blasting process, the amount of steel shot into the shot blasting machine is certain. When the cut shot is too long and the flow is not good, it will prevent more steel shots from flowing downward, thus reducing the amount of steel shots required per unit area. The efficiency of shot blasting is reduced, the speed of workpiece shot blasting is affected, and the effect of shot blasting is affected. 6, when the cast steel shot or cast steel sand is broken, the surface roughness of the workpiece is not uniform after shot blasting. This situation is good or bad. After adding new cast steel pellets or cast steel sand, the roughness will be slightly better, and after adding and using for a period of time, the roughness will change greatly. 7, because the cast steel ball or cast steel sand is easy to break, it increases the cost of consumables for users, produces a lot of dust, and shortens the life of wearing parts. Many companies have begun to use more environmentally friendly and durable steel balls, such as steel mills, shipyards, auto parts, medical equipment, aviation, etc. 8. Why do we recommend the use of reinforced steel pellets? (See annex on next page)

Annex: Why it is recommended to use reinforced steel shot 1. Why is it recommended to use reinforced steel pellets? (1) The characteristics of cast steel pellets (cast steel sand) : 1) Because cast steel pellets (cast steel sand) are made of castings, cast steel pellets (cast steel sand) will be hollow due to porosity during the casting process, and cast steel pellets (cast steel sand) will also be hollow. The steel shot (cast steel sand) has a high brittleness, which determines that the cast steel shot (cast steel sand) is easy to break due to impact in the process of high-speed projection, resulting in fast consumption and high cost; 2) A large amount of dust will be generated after the broken steel pellets (cast steel sand), which will produce a great pressure on the filter element in the dust collector, which will easily lead to serious dust accumulation in the filter element and accelerate the damage of the filter element; 3) The wearing parts in the shot blasting machine are made of high chromium and high manganese materials, which are resistant to impact but not advection wear. When the amount of dust in the shot blasting machine is large, the dust collector can not be filtered in time. At this time, a lot of dust will enter the room